Problems encountered in industrial manufacturing using a pulsed laser beam are often similar. One problem is that the aim of laser beam should be correct. Another addition is the danger of getting too hot, which could cause an overall unpleasant product. Additionally, optimum levels of laser beam power need to be ensured for reliability. These issues underscore the necessity of choosing the state-of-the- art pulsed laser beam technology available on today ‘s market.

Another problem in the practice of pulsed laser beam technology is that of alignment of a working beam. If the laser is out of focus or misdirected, it may print imperfectly. In doing so, this can result in wasted materials and time as well as possibly defective products. To counteract this problem, periodically the manufacturers of such an apparatus must calibrate and align the LUMI intense laser pulse treatment to obtain peak performance.

Starting with the pulsed laser beam: With this technology, hot spots are known to occur. The high power laser beam can also create a lot of heat and thus may influence the material to be processed. Work-piece Warping: Overheating may warp, melt or otherwise damage the workpiece being processed to produce products of less than acceptable quality. To avoid overheating, manufactures need to be able to carefully track and adjust the power levels and length of each laser burst.

Sticking to a constant power level is also important in the case when pulsed laser beam technology is employed. Power fluctuations can cause changes in the quality and accuracy of the laser process. This can affect the productivity and quality of the manufacturing process. It is important to have high quality pulsed laser systems with accurate power control and stability to obtain reproducible results.

LUMI's pulsed laser systems also provide excellent power control and stability. The technology features sophisticated power modulation systems enabling tailored control over the power of each laser shot. Such an accuracy of application achieves uniform results and constant performance, which is why pulse light laser technology from LUMI has proven its worth in industrial shops-a guarantee for high quality.

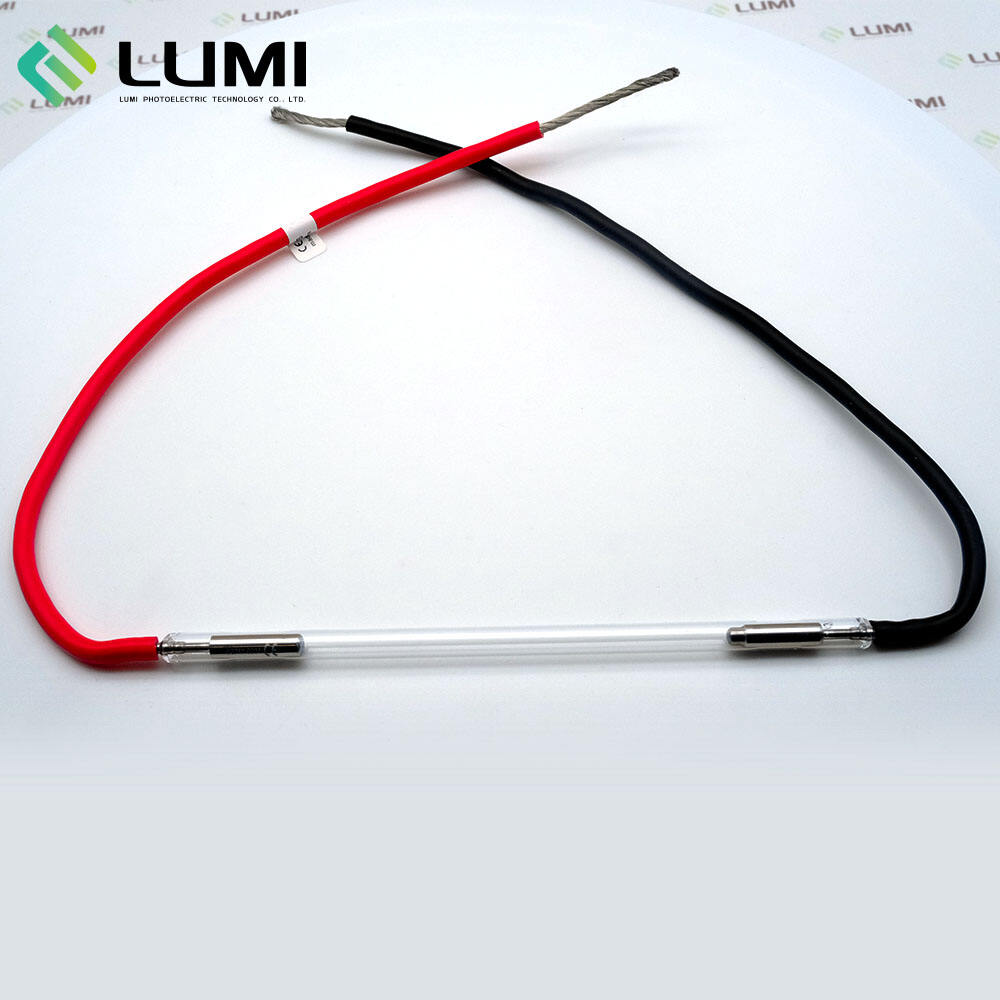

If you want to buy pulsed laser beam instruments from LUMI, the following is some crucial issues need to be considered before. First, consider what the equipment is going to be used for. Various pulsed laser beams are created with certain uses in mind, and it’s necessary to have the right one. Then, look at the laser beam power. Lasers with higher power would instead allow more energy to be delivered, but may also demand a complexer cooling system. You should also consider the wavelength of the laser, and its usage for materials. And lastly, think about how big and easily transported you want your equipment to be and any extra features that may be necessary for your particular use.

In the last decade, there have been several new developments in pulsed laser beam technology. Among the most important advances is better control of pulse duration of the laser source. This means better quality, for more effective & productive material processing including the ability to work with a larger variety of materials. Furthermore, laser diode technology has progressed to allow smaller, more power efficient lasers. Basically, this indicates that a user may now obtain higher power output with lower energy. Making LUMI impulse light laser technology more economical and eco-friendly.